When one is talking about the fully automatic sleeve wrapping machine, one might have even heard about it. But if one is looking for such equipment, then one needs to know about the device. In order to wrap anything in an automatic way, this equipment wraps the product of any size by the help of plastic film. To make the film tight, heat is applied to the surface. It confirms to the shape of the object and seats itself, as it wraps the product.

To sleeve wrap, there are multiple methods. With a handheld heat gun, smaller items may be placed in sleeve wrapper bag and then being heated. Adjustable in length, other items may be placed in a sleeve wrapping machine. In order heat, wrap and seal all the items at the same time, facilities can be provided as the sleeve wrapper can wrap large loads at the same time.

# Benefits Of Sleeve Wrapping Equipment

Across various industries, semi-automatic sleeve wrapping machine is used. It provides a wide range of benefits as well while being easy to use.

# Safeguarding The Product

There is the development of tight seal when heat is applied to sleeve wrapping device. The wrapped contents are fully protected, as the plastic seal wraps the products. By moisture, dust, and dirt, the wrapper cannot get destroyed. To keep the wrap of the products safe from the sun’s harmful rays, some wrappers even come with UV protection.

# Durability Of The Wrapper

Manufactured from durable plastic, the wrappers are very sturdy in nature. This cannot be easily punctured or tore. If there is extreme heat or cold weather, the wrappers which comes out of the machine does not become brittle. There will be no sag or loosening, ones the wrap has been sealed and heated.

# Tampering

Any tampering will be noticeable, since the wrapper wraps and holds the seals to its shape. Hence many pharmaceuticals companies use this machine to wrap the products. When the plastic has been stretched, some of the wrappers are being used to show that the sealed items have been touched.

# Branding Of The Product

With the words, colors, pictures, and logos, that can promote the product, sleeve wrapping machine can often use the various designs to brand the products. It will wrap the brand and will not only brand the product in a simple way. This will make better visibility for the customers while increasing the brand awareness.

# Conclusion:

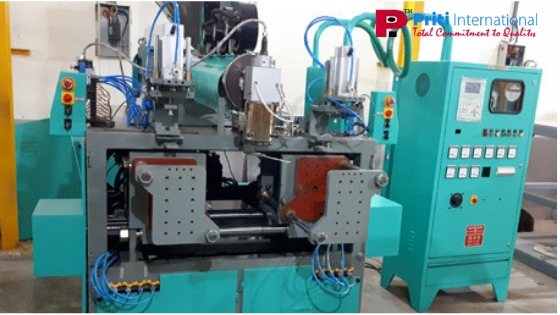

The shrink wrapping machine is one of the user machine used for wrapping of products. If one is looking for more information about the product, then one can come to “ Priti International”