Plastic bottles are commonly used by many companies. Due to its unbreakable nature it is easy to transport them. Their production is complex and so needs a robust machine with high tech technology. PVC molding machine can make this complex task simple and produces great quality plastic bottles fit for all the uses by the companies. HDPE which is high-density polyethylene is a machine that manufactures plastic bottles, containers, tanks etc. The plastics are made by the process of injection moulding. Manufacturing of glass bottles are also possible with it. The responsible companies use these machines as it not only produces multiple usage plastic objects but is also a safe method.

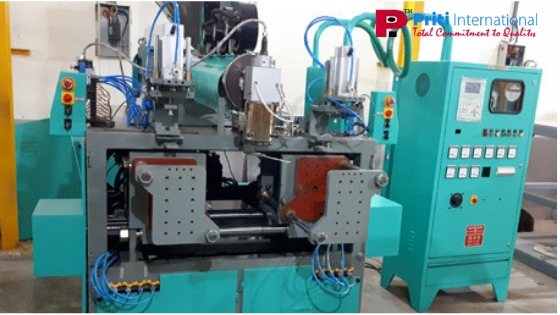

Powerful and effective machines

The innovative machines possess great features which makes it unique and powerful. Some of the features are single station or double with de- flashing or without it in various models. The machines can be double, triple head or even four or five head. They are also of different layers in zebra line head like 2, 3 or 4 layers. They contain bobbing extruders, viewing strip machines. The blowing can be done from bottom and there is also angular blowing attachment. It has different points of control; extruders are enriched with big screws. There are hot wire cutters and A.C drive with great output.

Extrusion, stretch and injection moulding are the three types of blow moulding. Three of them work in their own unique ways to produce great results. Larger companies require the use of injection moulding. It can produce huge quantity of plastics for multiple usages. HDPE moulding machine is the demand for the companies which requires plastic objects in a huge basis. There are also various methods of getting plastics out of these machines. The well knowledgeable team has been developing these machines since a long time to get effective results.

Priti International manufactures optimum machines which are highly efficient in meeting the industry requirements of plastics effectively. The excellent design and construction are the strength of the company. It is the fast developing company in water and waste water treatment field. It has an expertise in developing speciality market products that is the need of the advancing business world.