These days there are good Water Plant Manufacturer in Kolkata supplying packaged water to all. Here are the advantages and requirements of setting up a plant.

The bottled water that we use today is nothing but mineral water. Though the mineral water originally used was actually from the naturally available mineral springs. Because of its therapeutic properties people would then go to areas where there were natural springs and bring water from those areas. The water was used not just for drinking but also for bathing. The enterprising few took advantage of this and began to bring this in bottled form and then sell it. Nowadays the mineral water that we refer to is actually sparkling water which is carbonated or it may be still water if no added gases are there. These water are now manufactured by Water Plant Manufacturer in Kolkata from where this water is supplied to different parts of the state and the nation.

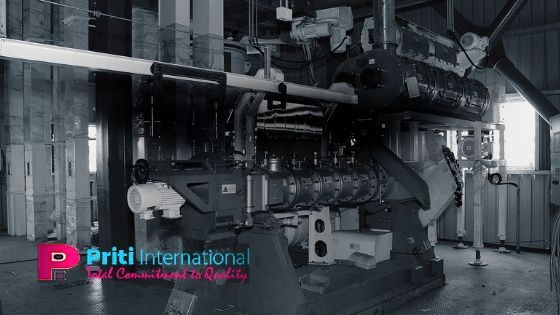

The packaged drinking companies carry out the process of bottling of water whereby the treatment of water, addition of essential minerals and packaging for reaching out to different parts of the country. Manufacturing of packaged drinking water is very profitable because:

- Being health conscious today, people place a lot of importance on health and hygiene factor and are very conscious about drinking water. They avoid drinking water from unknown sources. The bottled water is safe and tamper proof and ensures about the quality of water that is being drunk. Moreover these are treated water where minerals are added , which is essential for the body. All these factors make the water suitable for drinking purposes and hence there is always a heavy demand for the same.

- It is a very profitable venture because the primary setting up of the plant is the major expensive part but once that is done, the other costs inclusive of the cost of raw materials is much less.

- Water is not a perishable item and though there is always a shelf life for a packaged item, the longevity of water is much more, The chances of loss is minimum.

- It is much easier to store water than other food or perishable items.

One can opt for a soda water plant alongside for maximizing profit. The primary requirement for having a good packaged drinking water plant is to have a good manufacturer with the following qualities-

- Experience of water treatment in application. In this regards, turnkey project consultants are always an added advantage.

- Credibility of the manufacturer including of required certifications

- Reputable client list with whom there would have been a previous working experience

- Working partnership with well known brands

- Availability of different models as per the financial capacity of the client

- Availability of experts for round the clock support and for training purposes

- Hassle free maintenance support system.

These are the basic requirements for setting up a water manufacturing plant which is indeed a lucrative business today.